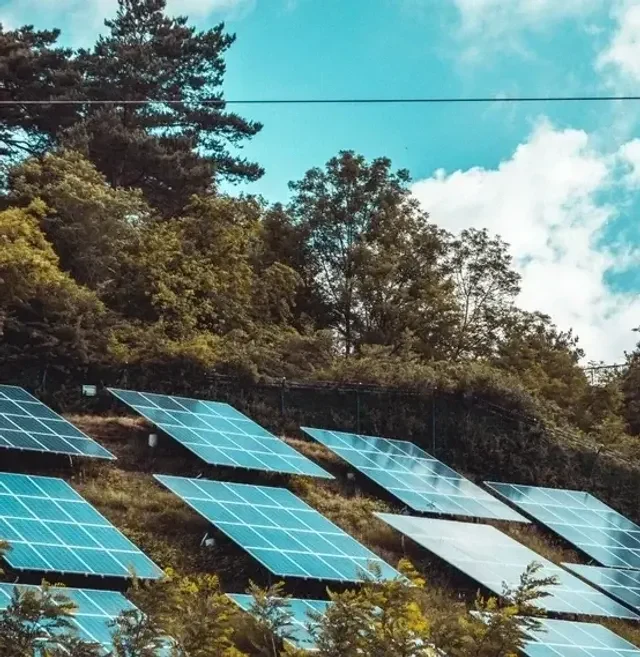

Where the fabrics are dyed, the water is recovered, cleaned and recirculated then used again. It’s a closed-loop process. At the end, the water coming out of the filters and going back round to be reused again is crystal clear, literally clean enough to drink; which we show in the video above. Teemill’s organic cotton is grown in the North of India where monsoon rains provide the water needed to grow the crop. Organic farms also have the advantage of maintaining a soil quality high enough to grow other crops, including food, in the dry season which reduces pressure on the water table when it is traditionally most stressed.

Teemill prints to order, meaning that there is no waste of overstocked products, and less demand for the materials and the natural resources used to make them, including water. In the wet processing factory, a closed-loop water system is used in the washing, dyeing and finishing processes, where the used water is purified and reused again and again, minimising water use.